Policies related to pollution

Gunvor has documented its policies and expectations in relation to Health, Safety, Environment, Human Rights and Communities in a formal document called “Group HSEC Policy”. Pollution is covered in the MDR-P section. Please refer to this section for further detail.

E2-2This is small tooltip textActions and resources in relation to pollution

In our business, pollution risks are mainly present during the transport of products and at our operational sites.

The risks during transport are managed by a range of measures, such as the vetting of vessels and barges, adherence to transport safety regulations and arrangements for emergency response.

The sites under our operational control are governed by strict environmental permits and regulations. A key framework is the European Industrial Emissions Directive (IED), which regulates permits for major industrial activities to minimize pollution to air, water, and land, while aligning operations with environmental protection objectives. The IED sets Emission Limit Values (ELVs) based on Best Available Techniques (BAT) conclusions, applicable to sectors such as refining, large combustion plants, and chemical waste treatment.

Gunvor’s industrial sites comply with applicable BAT standards and continuously work to further reduce emissions, resulting in detailed permit requirements. Dedicated Health, Safety, and Environment (HSE) departments at each site oversee compliance, environmental monitoring, improvement measures, and incident and emergency management.

Regulatory compliance is integrated into our 13 HSEC standards, which include specific environmental requirements. Compliance is monitored through regular reporting and audits.

E2-3This is small tooltip textTargets related to pollution

Gunvor has established pollution-related targets to support its environmental policies. The primary focus is on avoiding losses of containment, such as spills and leaks. Gunvor also focuses on reporting of any exceedances of permitted emission levels and complaints about nuisance.

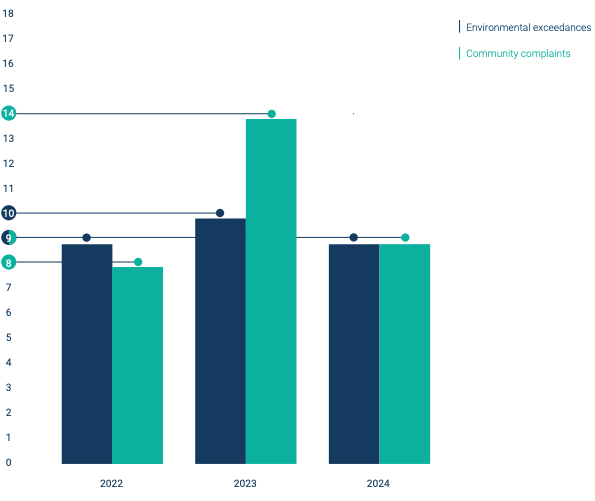

2024 Performance Overview

Gunvor’s management rigorously maintains operational compliance, promptly addressing and investigating regulatory breaches to prevent future occurrences. In 2024, there was decrease in both complaints and exceedances compared to 2023 as illustrated in the following graph. The assets exceedances mainly involve short term air emissions, with two exceedances related to wastewater. Examples include brief SO2 emission exceedances as a result of operating mode changes and analyzer issues. Furthermore, Gunvor’s assets were not subject to any fines by complying with environmental regulations and actively collaborating with local communities to resolve concerns about operational effects.

Gunvor operational sites – environmental exceedances & community complaints

About this graph: The numbers of environmental permit exceedances and community complaints around Gunvor’s operational sites.

Pollution of air, water, and soil

Gunvor is committed to maintaining environmental norms, adhering to the applicable regulations. Our industrial sites follow strict emission regulations, consistently overseeing and documenting pollutant levels both internally and to respective authorities.

Air Emissions

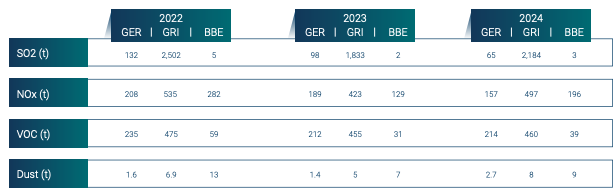

The most relevant air pollutants at Gunvor’s production sites are Sulphur Dioxide (SO2), Nitrogen Oxides (NOx), Particulate Matter (dust), and Volatile Organic Compounds (VOCs).

The main source of Nitrogen Oxides (NOx) are the furnaces and gas turbines where a small part of the nitrogen in the combustion air reacts with oxygen depending on the conditions in the flame. Gunvor has equipped many of its furnaces with low NOx burners to reduce emissions. Emissions from VOCs are controlled by means of vapor recovery systems, equipment on floating roof tanks, and leak detection and repair programs. Sulphur dioxide (SO2) originates from sulphur in the fuel used at the company’s plants and from the regeneration of the catalyst in the Fluid Catalytic Cracking unit (FCC) at our German refinery (GRI).

Through several measures, such as the use of natural gas instead of oil as fuel, Gunvor has significantly reduced the SO2 emissions in the past. These measures also have reduced the emission of particulates such as soot particles. Further reduction of SO2 emissions followed from the installation of an SO2 scrubber at the FCC unit in our Ingolstadt Refinery in 2023.

Air emissions are measured according to the permit requirements on a continuous or periodic basis. When measures show that a concentration is higher than what is permitted, this is reported as an exceedance. The following table shows the emissions for Gunvor’s refining sites and the powerplant acquired in 2024 (BBE). The emissions from the refineries in 2024 reflect a higher activity at GRI compared to 2023 when a major maintenance stop took place at that site, and a lower activity in the Rotterdam facility (GER), where the production was suspended in November- December.

The emissions from our powerplant in Bilbao (BBE) are strongly correlated with the highly variable electricity production.

Air emission limit values were exceeded on 7 occasions, due to short term upsets in production processes

Air Pollution Table

Water Emissions

Gunvor’s production sites are equipped with wastewater treatment plants, which are subjected to monitoring requirements and other permit conditions. Various parameters are being monitored on a daily, weekly or monthly basis, depending on the type of substance, and compared with the emission limit values. The type of contaminants, monitoring frequencies and the associated emission limit values differ for each production site; hence it is difficult to report totals. We consider the number of exceedances of emission limits as being more relevant. When such cases occur this is reported as an incident and measures are considered to prevent recurrence. For details on environmental limit cases recorded in 2024, refer to the graph in the previous section. In 2024 there were 2 exceedances associated with wastewater emission limit values. In both cases the chemical oxygen demand (COD) was exceeded. This is a measure for the total load in the wastewater. This was due to a disturbance in the wastewater treatment.

Gunvor’s shipping branch Clearlake reported two incidents that resulted in spills to surface water. One spill concerned around one barrel of oil that was released by a failing loading hose. The other incident involved a solution of aqueous urea from an Intermediate Bulk Carrier (IBC) that fell overboard. In neither case there were significant environmental consequences.

Soil pollution

Pollution of soil may take place in case of leaks and spills. Such occasions need to be reported internally through our incident management systems to define appropriate measures. Losses of containment and spills to unprotected ground or the surface water are reported as performance indicators monthly. Spills are reported in two metrics: above and below one barrel (159L). At Gunvor’s production sites we experienced one spill in a size above one barrel in 2024: 350 litres of crude oil escaped from a drain line at one of our refineries. As a rule, each spill is followed by cleaning up or remediation works.

Substances of concern and substances of very

high concern

Substances of Concern (SC) are considered those substances that meet the following classifications according to the European CLP Regulation (which implements the globally harmonized system of the United Nations for the classification and labelling of chemicals):

The following classification according to the European Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation:

Gunvor trades many petroleum products, and the following fuels meet the criteria listed above with respect to carcinogenicity (Carc.), mutagenicity (Muta.) or Reprotoxicity (Repr.):

(Category 1B stands for presumed, category 2 for suspected)

In addition, feedstocks such as crude oil and naphtha and certain refinery intermediate streams also meet the criteria listed above.

For an impression of the quantities of the traded Substances of Concern we refer to information in the business sections of the annual report.

It should be kept in mind that a classification like presumed carcinogen does not mean that the substance poses a risk during normal use. The classification is based on intrinsic hazardous properties as determined with e.g. animal testing and not on risk assessment. Risk Management Measures are designed and prescribed to keep the exposure within acceptable limits. For example, the gasoline we sell is to be used as fuel. During such use, there is no exposure to the substance that could result in a relevant risk. The allowed uses and the appropriate risk management measures are communicated to clients by means of Safety Data Sheets.

Currently none of Gunvor’s products are classified as Endocrine Disruptive or as Persistent, Bioaccumulative and Toxic.

Substances of Very High Concern

Substances of Very High Concern (SVHC) are considered those substances that are included in Annex XIV of the REACH regulation (substances subject to authorization) or substances on the candidate list for inclusion in that annex, published and regularly updated by the European Chemicals Agency. Gunvor does not trade such substances. However, some of the products we trade may contain SVHC as constituents in low concentrations. In particular, heavier oil products such as fuel oil contain Polycyclic Aromatic Hydrocarbons (PAH). This group consists of thousands of different constituents and some of them are on the SVHC list. Under normal use as fuel, this presence does not result in significantly elevated environmental or health risks if the appropriate risk management measures are applied.

CASE STUDIES

Click below for more detailed information